1. Lock parking lever.

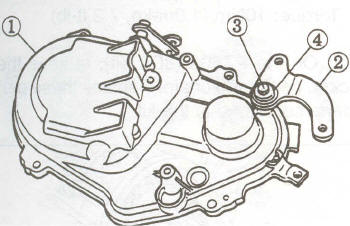

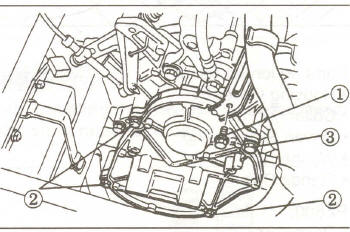

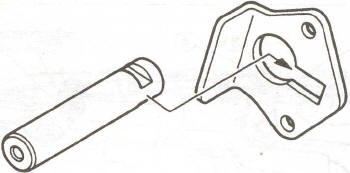

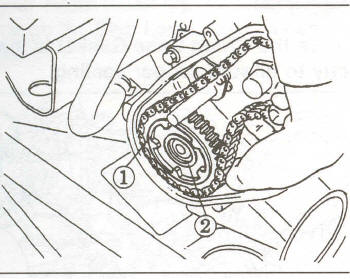

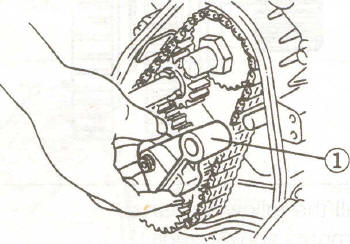

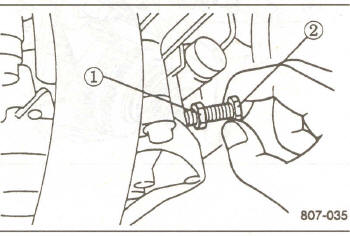

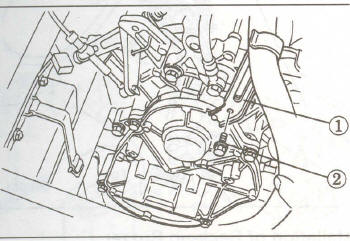

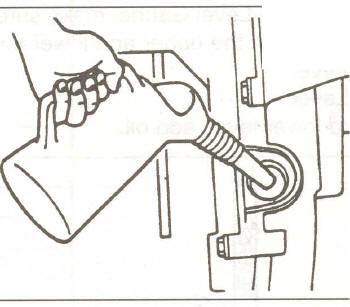

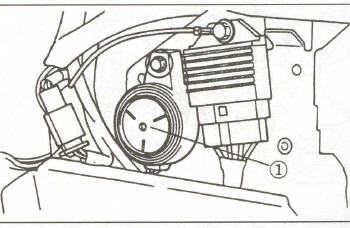

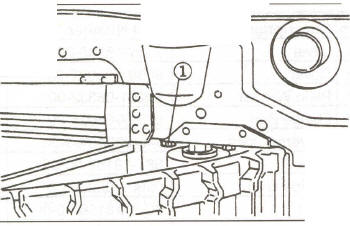

2. Drain gear oil. Roll vehicle onto the left side. Loosen drain bolt CD. Roll vehicle back upright.

Place a drain pan beneath the drain bolt. Remove the drain bolt and drain oil. After draining oil, replace the drain bolt.

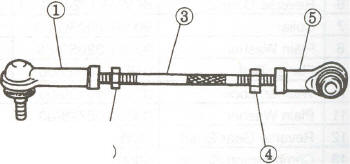

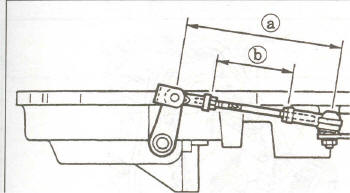

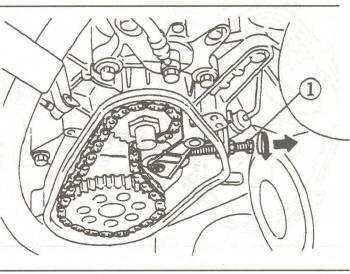

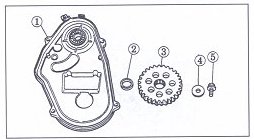

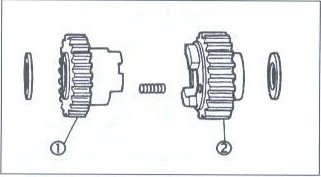

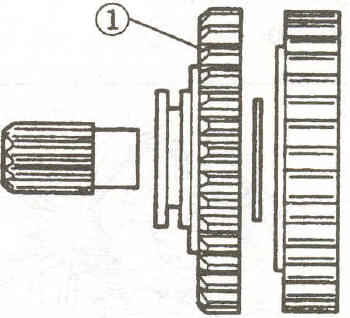

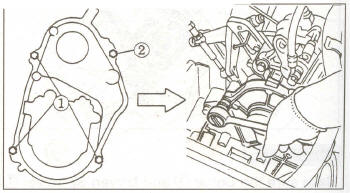

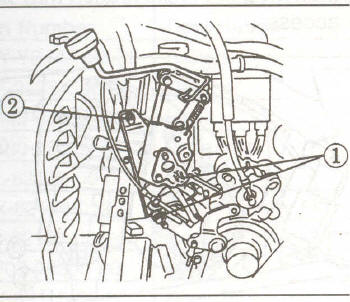

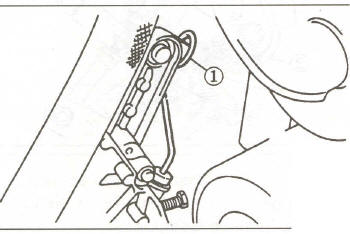

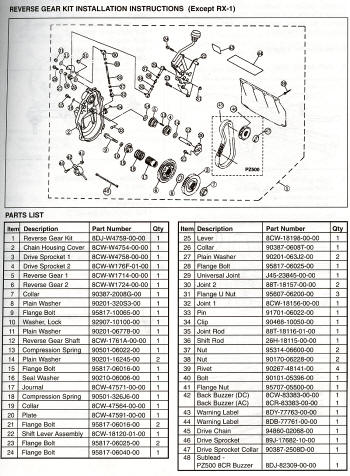

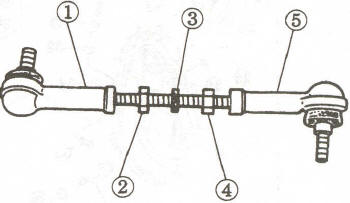

1 . Assemble Shift Rod Assembly

Universal Joint (right-handed screw) (1), Nut (right-hand thread (2), Shift Rod (3), Nut (left-handed thread) (4) Joint 2 (left-handed thread) (5).

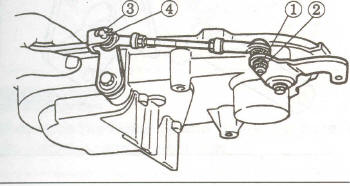

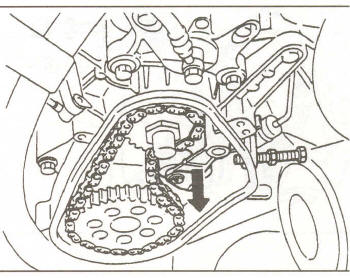

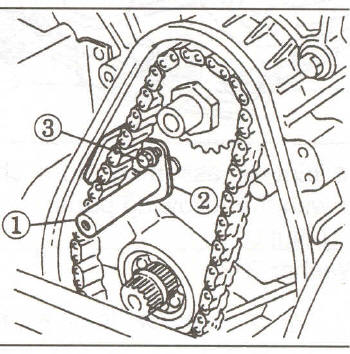

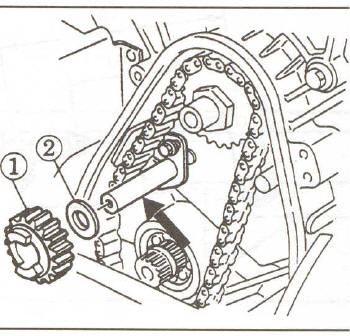

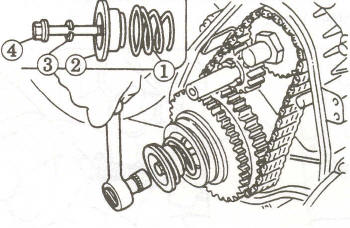

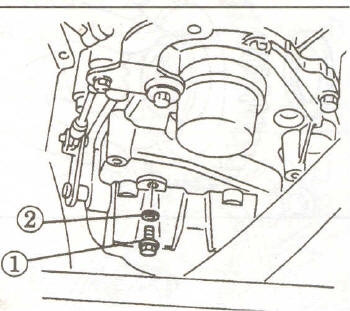

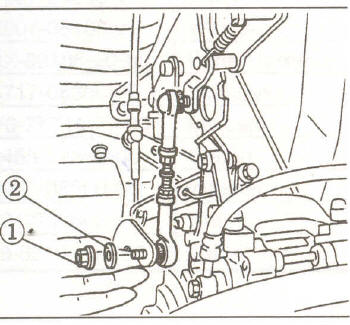

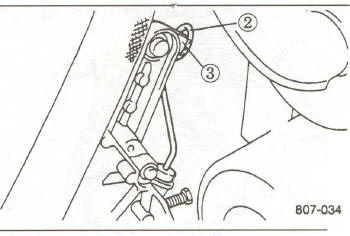

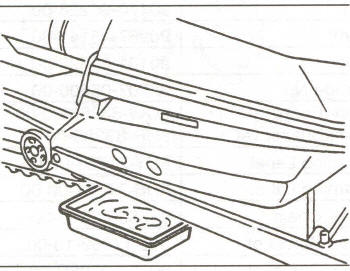

2. Assemble Joint Rod Assembly

Joint 2 (1),

Nut (Right-hand thread) (2), Joint Rod (3), Nut (Left-hand thread) (4), Joint

1 (5)

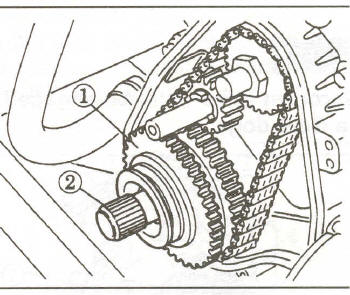

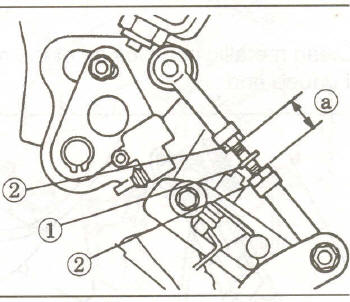

CAUTION

Be sure the rotating direction of threads are cor- rect when assembling the shift rod and joint rod assemblies.